Dynamic replacement is an adaptation of the dynamic compaction process for organic, saturated or weak cohesive soils.

The operational process is similar to that of dynamic compaction, involving dropping a heavy weight, but in this instance, coarse stone aggregate is introduced at the surface. This coarse aggregate is punched into the soils to create large diameter pillars of stone typically up to 2m in diameter.

Benefits

- Enhanced bearing capacity

- A reduction in the total and differential settlements

- An increase in the permeability allows acceleration of anticipated settlements

- Ground bearing foundation solutions can be adopted reducing the need for reinforced foundations

- The displacement process creates no spoil

Application

- Commercial/industrial foundations and floor slabs with high tolerances

- Infrastructure schemes including embankments, water treatment plants and windfarms

Presentation and key elements

What is Dynamic Replacement and when is it suitable?

Dynamic Replacement combines the benefits of Dynamic Compaction and Vibro Stone Columns to create large-sized dynamic replacement inclusions or pillars with high internal shear resistance. As a solution, Dynamic Replacement is well suited to weak, organic or compressible soils or structures with high loading such as storage tanks or high backfill structures.

This reinforcement technique improves the bearing capacity of poor soils and reduces differential settlements, whilst also allowing rapid ground drainage.

Fundamentals of Dynamic Replacement

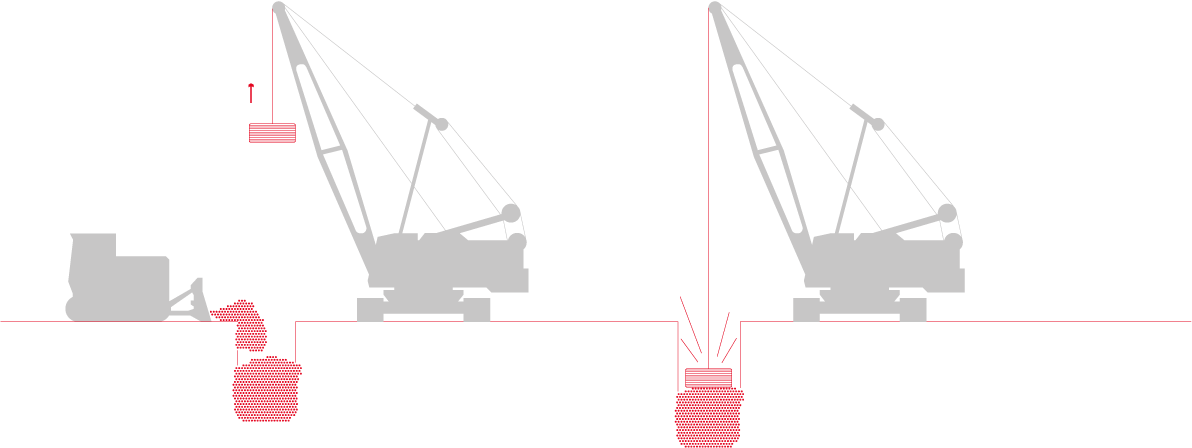

Where weak or organic soils are present such that Dynamic Compaction is not viable, the Dynamic Replacement technique can be deployed. A fill material is added, and the incorporation ratio of this is typically between 10% and 15%.

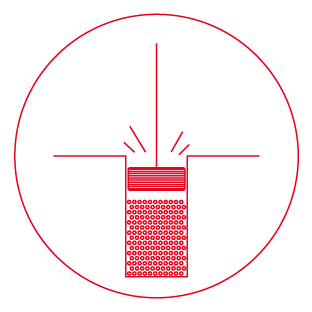

During construction, the tamping energy drives the granular material into the compressible soil below, forming large reinforcement columns, with large diameters typically up to 2 metres. Further ground improvement is possible within the underlying layers through the transmission of the energy of the weight at depth.

Dynamic Replacement execution

The process can be undertaken with or without pre-excavation. Alternate pounding and filling of the pillars are carried out during execution. The material to be incorporated is either placed on the surface prior to commencement or is added at regular intervals throughout the works.